What is Mashing?

Mashing in brewing is the process where water is mixed with milled or crushed grain which allows the brewer to make wort. Compounds in the grain such as sugars, proteins, and enzymes are solubilized by the water. Enzymes will also transform insoluble compounds like starches into more soluble compounds.

There are many physical and (bio)chemical processes that happen in the mash. There are different enzymes that are active, or working, at different temperatures and different pH ranges.

The brewer can manipulate these enzymes at certain temperatures for various amounts of time to have more control of the final wort produced. These temperatures are called rests.

Types of Rest

Here’s a table summarizing the mash rest steps we will be discussing:

| Rest | Temperature (°C) | Temperature (°F) | Function |

| Acid (Phytase) | 35 °C | 95 °F | Breakdown phytin, lower mash pH |

| Acid (Ferulic) | 45 °C | 113 °F | Release ferulic acid from barley/wheat malt for production of 4-vinyl guaiacol |

| β-glucanase | 45 °C | 113 °F | Breakdown β-glucans that contribute to “gumminess” of mash to prevent stuck mash/sparge |

| Protease | 50 °C | 122 °F | Breaks down long chained proteins into medium length chains |

| Peptidase | 50 °C | 122 °F | Breaks short to medium chained peptides into component amino acids |

| β-amylase | 60 °C | 140 °F | Convert starches into simpler sugars |

| α-amylase | 70 °C | 158 °F | Convert starches into simpler sugars |

| Mash out | 75 °C | 167 °F | Reduce viscosity of wort to aid in sparge |

There is a traditional method of mashing called decoction mashing which, while not discussed here, is an interesting topic for another day. The act of performing decoctions is a way to adjust the temperature of the mash to the different rest temperatures while creating a robust, complex flavor profile to the canvas of the wort, and ultimately, the finished beer.

Acid Rest

Phytase Rest

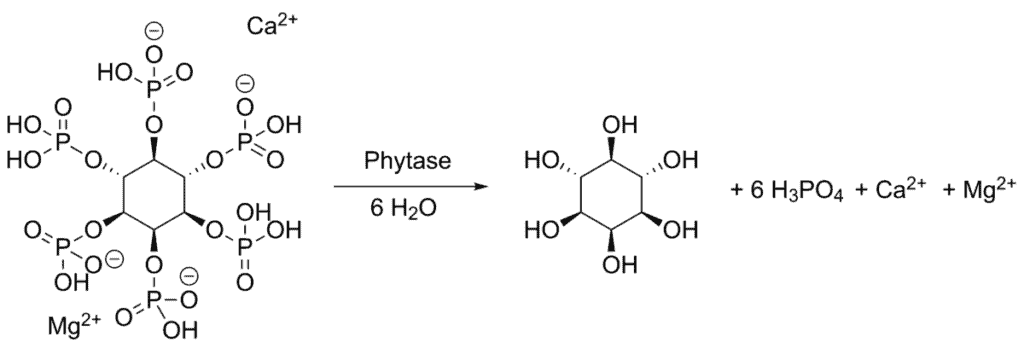

The acid rest allows an enzyme called phytase to break the molecule phytin down into phosphoric acid (as well as calcium phosphate and magnesium phosphate) which helps to lower the pH of the mash.

What is the temperature range for an acid rest? This rest is usually performed at 35-40 °C for an extended period of time with very lightly-kilned malts, such as pilsner malt, or with low mineral content water. Although, most homebrewers skip this step and opt for adjusting the water chemistry with various brewing salts and acids instead. Adjusting the water chemistry via these methods provides a bit more consistent control from batch to batch of beer.

Ferulic Acid Rest

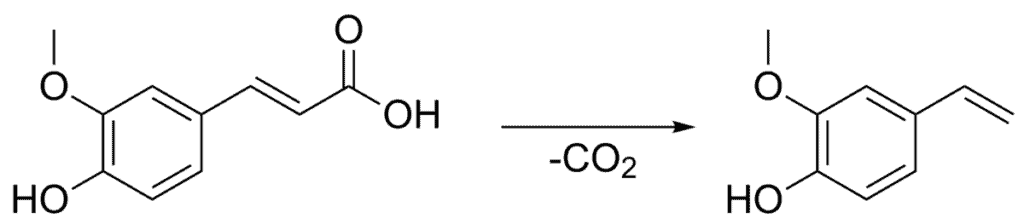

Ferulic acid is a phenolic phytochemical that is a precursor to 4-vinyl guaiacol, which is responsible for the clove, medicinal, or spicy quality of beers like weissbiers.

The conversion of ferulic acid to 4-vinyl guaiacol occurs via thermal decarboxylation, or loss of carbon dioxide, CO2, during boiling of the wort, as well as via enzymatic decarboxylation during fermentation by phenolic off-flavor positive, POF+, phenotype yeasts.

What temperature is a ferulic acid rest? This particular rest typically occurs at 45 °C and is typically used in weissbier production.

β-glucanase Rest

Understanding this numbering scheme will also help when we talk about the amylases involved in the saccharification rest.

Before we jump into what enzymes are involved in this particular category and how they work, let’s cover some vocabulary. We’ll be referring to types of bonds (glucose molecule to glucose molecule, or glucosidic bond, in this case) that enzymes will break (via hydrolysis).

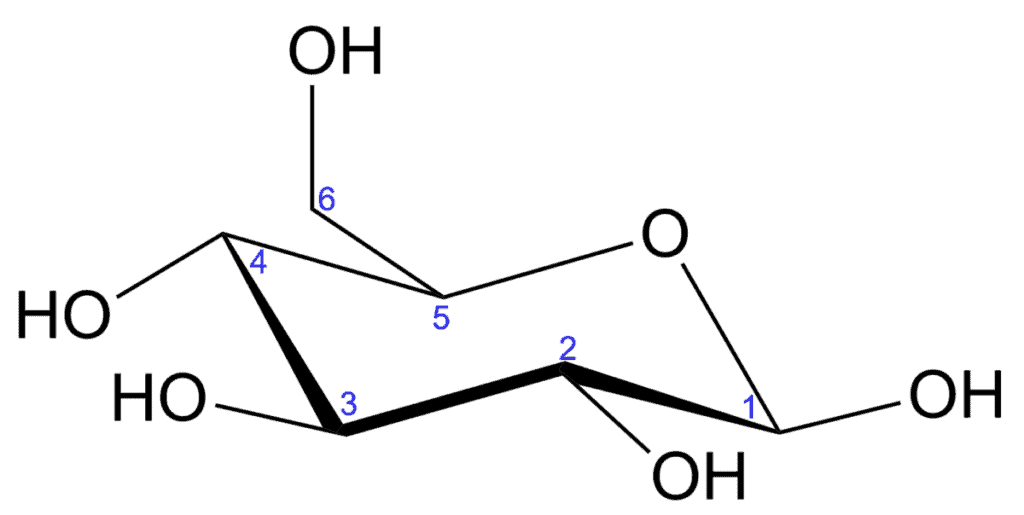

In the figure below, I’m showing the numbering convention for the molecule, glucose. We’ll be numbering the carbon atoms around the ring, starting clockwise from the oxygen atom (O). Notice the sixth carbon is outside of the six-membered ring.

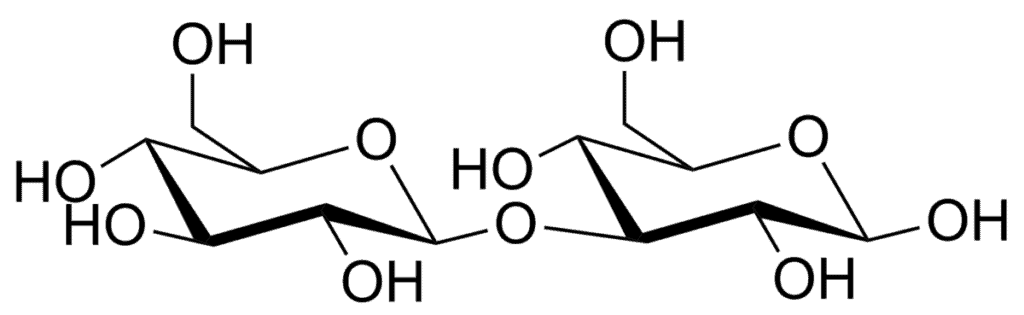

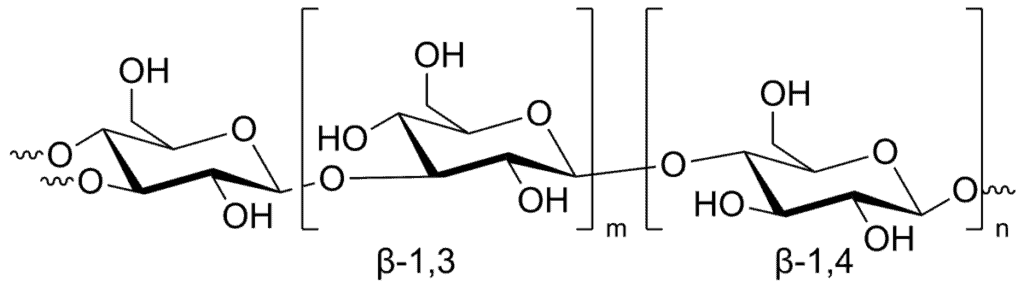

β-glucans are molecules that consist of glucose units that are connected via 1,3 or 1,4 linkages in the β-form.

These glucose units are repeating units (monomers) in a much longer sequence or polymer. In the figure below, we’ll see that there can be two repeating blocks, or copolymers, with a certain number of these repeating units (m and n after the brackets for the β-1,3 and β-1,4 linked glucose units, respectively). In barley, m = 3 to 4, whereas n = up to 20. (ref)

The β-glucans can cause high viscosity in the mash. This is particularly evident when using unmalted grains such as flaked oats, flaked wheat, flaked barley, and flaked rye–high amounts of these ingredients can lead to a gummy mash that could also lead to a stuck sparge, or rinse of the sugars from the grain bed.

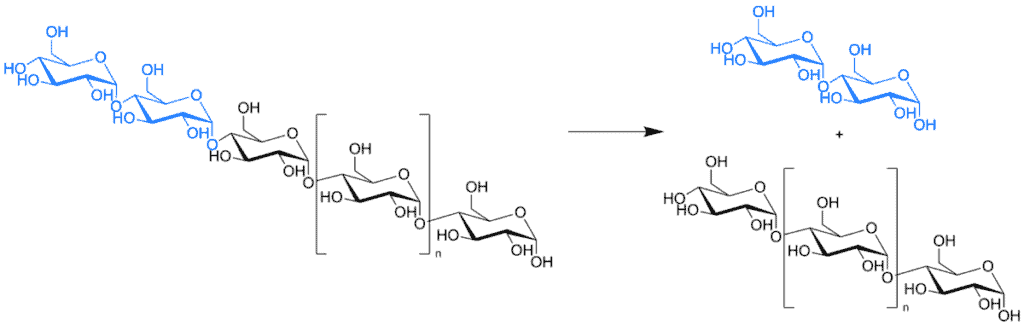

β-glucanase will hydrolyze β-1,4 linkages that are adjacent to a β-1,3 linkage. This breaks the β-glucans into smaller units, which will decrease the viscosity of the wort.

β-glucanase is most active with a temperature of 40-50 °C. A β-glucanase rest can be used to prevent gummy mashes/starches.

One disadvantage of performing a β-glucanase rest is that the breakdown of β-glucans can lead to reduced clarity in end beer.

Protein Rest

A common rest for mashing malts not highly modified is the protein rest. This rest is usually performed around 50 °C. Proteases break down high molecular weight proteins into lower molecular weight proteins. Breaking down the longer protein chains can help boost head retention and minimize haze in the finished beer.

Another enzyme that is active at this temperature is peptidase. Peptidase breaks down small proteins into their component amino acids. These amino acids are used by the yeast during fermentation.

A word of caution: The protein rest should not be used when using highly modified malts. Since highly modified malts do not have as much protein available to be dissolved in the wort, whatever protein is there will be reduced to small components. As a result, the finished beer will likely have very little head retention and will have a thinner body than what was intended by the recipe.

I’d suggest that unless you’re using a floor-malted variety, limit or avoid the time spent in the protein rest stage.

The Star of the Show!: Saccharification Rest

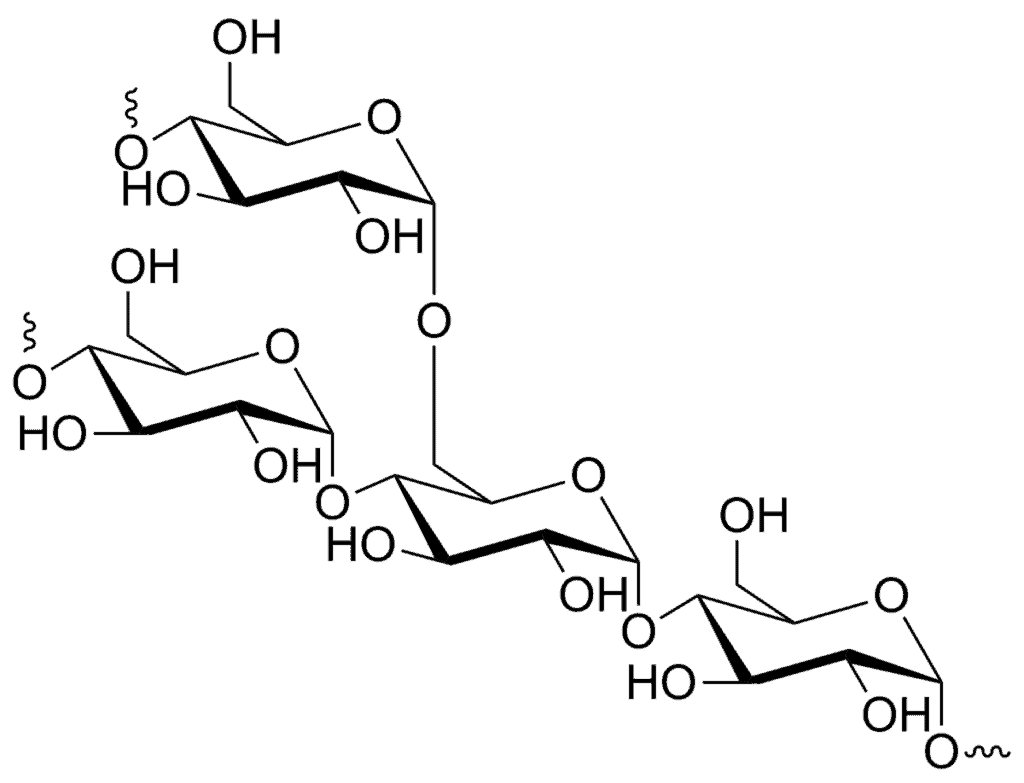

The saccharification rest is where starches are broken down into smaller pieces, such as sugars. As shown in the figure above, we’ll be referring to how bonds in the starches are broken by the amylase enzymes. There are two amylase enzymes that are present in the malt that are responsible for breaking starches, such as amylose and amylopectin, down into sugars, such as glucose, maltose, and maltotriose, as well as compounds called “dextrins“.

Amylose is a starch composed of α-1,4 glycosidic bonds. As a result, the structure of amylose is a linear chain that forms a helix. Amylose accounts for approximately 30% of starch in malted barley.

Much like amylose, amylopectin is a starch composed of α-1,4 glycosidic bonds. However, in addition to this “linear” backbone, there are branches of glucose chains due to α-1,6 glycosidic bonds.

The amylase enzymes are responsible for catalyzing the hydrolysis of the starches into simpler sugars. Here, we’ll be talking about alpha and beta amylases.

Up first: β-amylase!

β-amylase

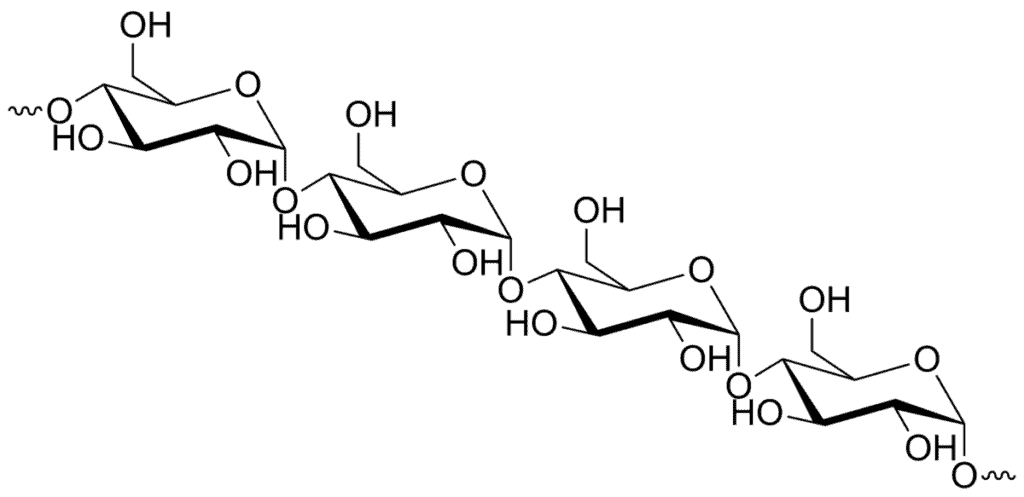

β-amylase catalyzes the hydrolysis of α-1,4 linkages, working from what is called the non-reducing end of starch. It cleaves off a two-glucose unit called maltose.

When “consuming” amylose, β-amylase acts sort of like Pac-Man; chomping away until either it runs into an obstacle, or it runs out of “dots” or glucose.

So, when consuming amylopectin, the α-1,6 linkages create an obstacle for β-amylase, leaving larger portions of the starches untouched once β-amylase “chews” up the preceding α-1,4 linkages. These larger portions are part of a class of compounds known as dextrins.

β-amylase is optimally active between 54 °C and 66 °C at a pH of 5.2-5.5.

α-amylase

Rather than operating from one end of a starch molecule like its β-amylase cousin, α-amylase attacks the starch at random points. Imagine cutting a string at random with scissors. As a result, α-amylase produces maltose and maltotriose (a three-glucose unit sugar) when consuming amylose.

α-amylase is quite bulky, in terms of its size and shape, so it cannot “cut” too close to the branching points in amylopectin created by the α-1,6 linkages. Here, it produces maltose, glucose, and dextrins.

α-amylase is optimally active between 68 °C and 72 °C at a pH of 5.2-5.5.

Final Rest–The Mash Out

The mash out, or mashout, is a step performed at the end of the mashing process, prior to the sparge, or rinsing of the grain bed. Although sometimes omitted by brewers, this step is important and is used to loosen up the sugars from the grain for ease of sparging. This reduces the viscosity of the wort so flow through the grain bed is increased, resulting in more efficient rinsing of the sugars from the grain.

The mashout step is also thought to increase the rate at which the amylase enzymes are denatured, or deactivated. This can prevent a reduction in the body or residual sweetness of the finished beer since the amylase enzymes could continue working during the sparge step, which can take up to an hour or more to complete.

The mashout step is usually performed at 75-80 °C.

Typical Mashing Techniques for Homebrewers

Single Infusion Mash

Since highly modified malts are widely available, many brewers opt for a simplified mash: the single infusion mash. The mash is usually held between 63 °C and 68 °C which allows β-amylase and α-amylase to work together at converting starch into sugar.

Mash Schedule 1: The Two-Step

An alternative to the single infusion mash is to have two rests to allow β-amylase and α-amylase to work near their optimal temperature.

The mash is held at 62 °C for 30 to 45 minutes before the temperature is raised to 71 °C for 30 to 45 minutes.

This type of step mash procedure promotes a highly fermentable wort.

Mash Schedule 2: Give Me Three Steps, Mister

If you were using an under-modified malt like floor-malted barley, performing a step mash that incorporates a protein rest before the saccharification rest would be beneficial to break down some of the larger proteins present in the malt.

A typical profile for brewing a European-styler pilsner would have a rest at 50 °C for 20 to 30 minutes, then heated to 60 °C for 30 minutes, and finally another rest at 70 °C for 30 minutes.

As mentioned before, if using highly modified malts, the protein rest is largely seen as unnecessary due to modern malting technology and high protein modification of malts.

Mash Schedule 3: Maximum Fermentability

A modification of the two-step mash profile mentioned earlier, type of step mash process is called Hochkurz; hoch meaning “high” and kurz meaning “fast”. The Hochkurz mash is held at 62 °C for 30 to 45 minutes before the temperature is raised to 71 °C for 30 to 45 minutes. The mash is then heated to 77 °C for a 10 minute mashout step.

My Preferred Mash Schedules

I usually employ two different mash profiles, depending on what I’m brewing.

For most beers, I use a single infusion mash at 65 °C for 60 minutes, followed by a mashout step at 75 °C for 10 minutes. The resulting wort produces a medium body in the finished beer.

For styles with a drier finish like pilsners or cream ales, I use a Hochkurz-type mash profile:

- 60 °C for 30 minutes (for β-amylase to do its thing)

- 70 °C for 30 minutes (for α-amylase to do its thing)

- 75 °C mashout for 10 minutes

Conclusions

There are many tools available to brewers to dial in on the quality of their wort. And there isn’t just one right way to brew beer.

A single infusion mash is simple. But if your brewing setup makes adjusting the temperature of the wort practical during the mash, step mashing is worth exploring.

Here’s a summary of the mash profiles we discussed earlier:

| Mash Profile | Example Mash Steps |

| Single Infusion | 65 °C or 67 °C (149 °F to 153 °F) for 60 minutes |

| Two-Step | 62 °C (144 °F) for 30 minutes 71 °C (160 °F) for 30 minutes |

| Three-Steps, Mister! | 50 °C (122 °F) for 30 minutes 60 °C (140 °F) for 30 minutes 70 °C (158 °F) for 30 minutes |

| Hochkurz | 62 °C (144 °F) for 30 minutes 71 °C (160 °F) for 30 minutes 77 °C (171 °F) for 10 minutes |

| Medium Body | 65 °C (149 °F) for 60 minutes 75 °C (167 °F) for 10 minutes |

| Dry Finish | 60 °C (140 °F) for 30 minutes 70 °C (158 °F) for 30 minutes 75 °C (167 °F) for 10 minutes |

Have fun and experiment! My view is: if you like what’s in your glass, you’re doing it right.

Cheers!

Resources

Coghe, S., Benoot, K., Delvaux, F., Vanderhaegen, B., & Delvaux, F.R. Ferulic Acid Release and 4-Vinylguaiacol Formation during Brewing and Fermentation: Indications for Feruloyl Esterase Activity in Saccharomyces cerevisiae. Journal of Agricultural and Food Chemistry, 2004, 52, 3, 602-608

Jin, Y-L., Speers, R.A., Paulson, A.T., & Stewart, R.J. Barley beta-glucans and their degradation during malting and brewing. Technical Quarterly, Master Brewers Association of the Americas 41 (2004): 231–240.